|

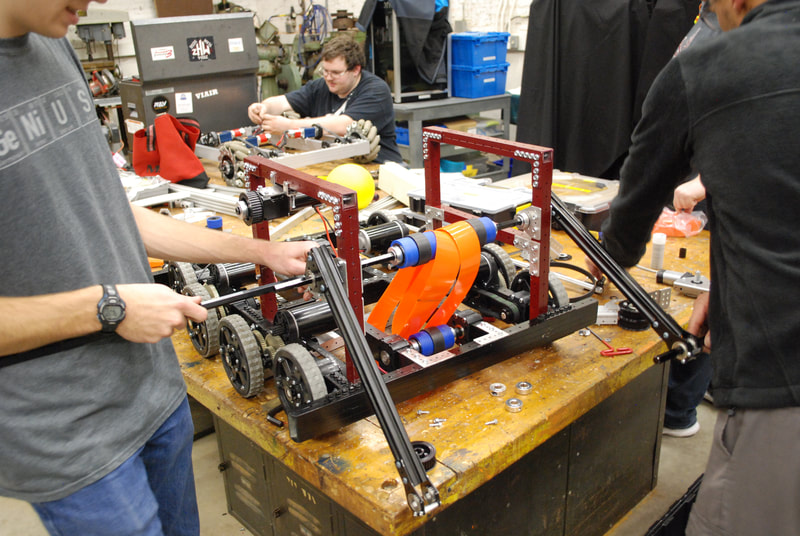

This week we accomplished quite a lot! We fixed the intake system and it is now fully functioning with only minor dead-zones and jamming that we are going to fix with aluminum strapping guides. The electronics were laid out, wired temporarily until wire connectors are delivered and received on Monday and then permanently attached and connected. One of our team members made and attached an electronics plate on Tuesday and then made and attached the simple color wheel manipulation mechanism on top of the robot on Wednesday. The building team then continued to build a battery shelf. Our machine parts also came in on Wednesday and turned out perfectly! With some sanding and drilling they were put unto the bot. The electronics team was able to get basic code to run all the mechanisms and then shooter assembly began on Friday and completely finished on Saturday. Winding down to the end of the week, the shooter was mounted on the robot and tested. It is extremely powerful and it is expected to perform well once all the bugs are worked out. Bumper backings were measured, cut, and the front and back of the robot frame was resized so a guard rail is able to be ran on the sides, keeping the wheels from being completely exposed. The bot was then weighed and is 115 pounds out of the 125 pound weight limit. A lot of work had been done on the field element as well, and our partial field is almost complete. Decisions were finally made on shooting on the back of the robot instead of the front, and we will NOT be having a turret as we realize it will not be feasible, and limelight is still to be determined. Good Luck with us and everyone else as we continue into next week!

1 Comment

The majority of the first half of the week was solving problems. There have been lots of issues figuring out how to drive the climbing mechanism. We are currently using chain to drive, but due to the shape of the mechanism, slack builds up once the climber is halfway extended until the chain is so loose that it just skips on the sprocket instead of doing any work. We also ran out of vital parts that had been ordered that should be here by the end of the week. On Thursday, we managed to build a solution to slack in our climbing mechanism. The building crew also mounted our full intake to the robot and are working on welding belts to use in the intake, though there were several significant issues that may or may not be problematic in the long run. Friday, progress was made on the second and third stages of the intake, attaching motors and welding belts. Progress is also definitely being made on the climber and is coming along, but we are still working on getting hooks and the crossbeam in place. By Saturday, a lot of catching up was done and the intake was completely finished being assembled. It was tested, though it did not work the first time, parts were 3D printed that should fix all of our problems. Our climber only needs hooks, which we should be able to retrieve off of Amazon, but in the mean time, our color-wheel manipulator has been cut and painted and should be ready to put on the bot by next week along with possibly laying out a plexiglass case on the "top shelf" of the robot to house all the electronics and the battery. A lot of small changes had been made

|

MegaHurtz Team Blog

Archives

March 2024

Categories |

|

MegaHurtz Robotics | FIRST Team 5056

Buchanan High School, Buchanan Michigan |

Our financial partner is Lake Michigan STEAMWORKS

More information can be found at www.lakemichigansteamworks.org |

RSS Feed

RSS Feed