|

Reference: https://firstinmichigan.us/FRC/

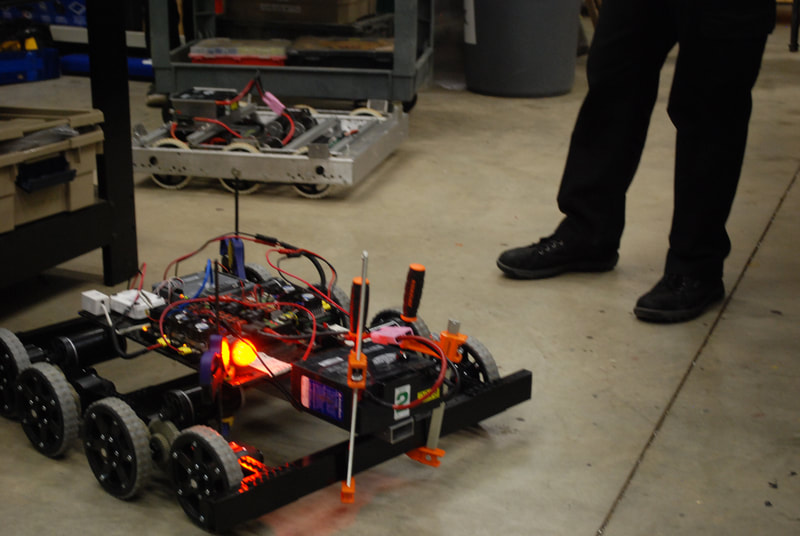

This was just sent out to all Michigan FIRST Robotics teams: ============== Due to the current and potential threat of the COVID-19 (Coronavirus) in our state and in accordance with public health recommendations, FIRST in Michigan has decided that, effective immediately, the upcoming FIRST in Michigan FRC District Events in our state will be postponed until further notice. We recognize that teams have put an enormous amount of work into preparing for the season and we regret having to share such disappointing news. At the same time, we feel strongly that this action is necessary given that COVID-19 cases have been confirmed in Michigan and the Governor has declared a State of Emergency. Please know this decision was not made lightly. It was made in consultation with FIRST, our University partners, and our sponsors, many of whom are represented on the FIRST in Michigan Board of Directors. Our primary concern is always the health and safety of our participants and our volunteers. We will continue to follow recommendations from the CDC, the State of Michigan Department of Health and Human Services, and local health departments as we monitor and assess the situation over the coming weeks to develop a plan to resume our FRC season and its events. =============== MegaHurtz Robotics WILL NOT be traveling to Gull Lake this weekend. We have a lot of very disappointed kids (and adults). Please give them your support. Over the weekend, MegaHurtz Robotics went to the St. Joseph District FIRST event at St. Joe High School. There they competed against 39 other teams from across the state. Buchanan's MegaHurtz Robotics FRC Team 5056 is made up of 12 students and six adult mentors. The team competed in 12 qualification matches and finished ranked #7/40 with 8 wins and 4 losses. During playoff alliance selection, the #3 seed invited MegaHurtz to move up. The new alliance did an amazing job first losing quarter final match one, winning two but unfortunately losing three which knocked them out of the competition. After the conclusion of match play, specific awards are given to teams in several distinct categories. MegaHurtz is the proud recipient of the Quality Award which: "Sponsored by Motorola Solutions Foundation celebrates machine robustness in concept and fabrication. The winning team demonstrates these characteristics in many ways from planning through execution. Building the robot is only part of their success and judges recognize them as a quality example to others." The award language reads: "Clean wiring with easy ACCESS PANELS for service instantly caught the judge's eyes. Their INTAKE SENSORS maintain power cell spacing no matter the FREQUENCY of their shooting. This clean and robust robot sets them up for MEGA success. Congratulations to team number 5056, MegaHurtz Robotics." MegaHurtz will be at the Gull Lake District event this weekend. March 13 and 14.

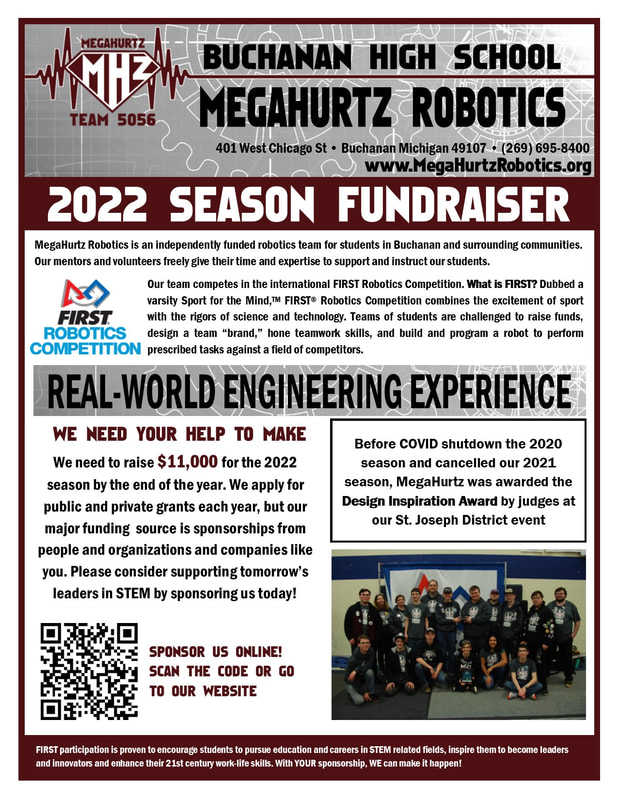

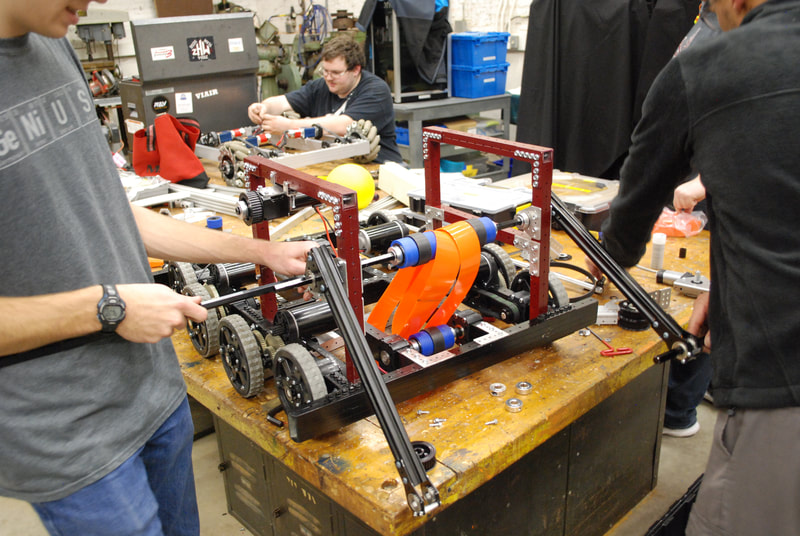

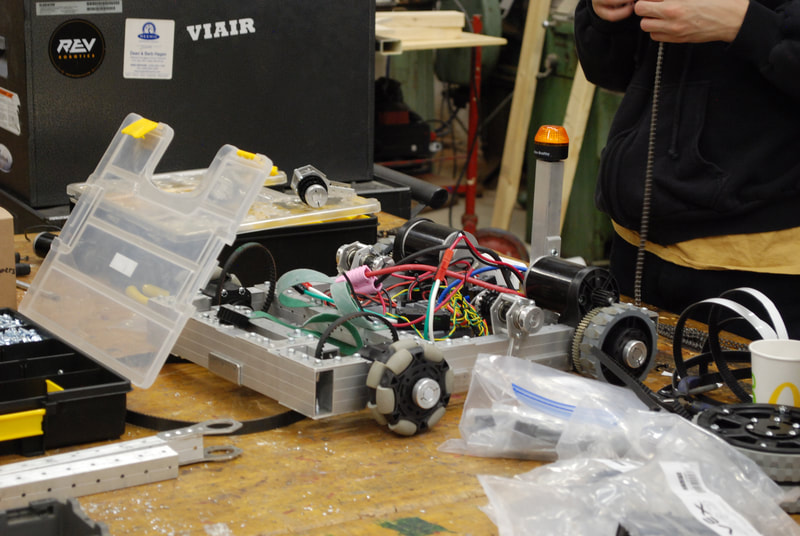

firstinmichigan.us/FRC/gull-lake/ This week we accomplished quite a lot! We fixed the intake system and it is now fully functioning with only minor dead-zones and jamming that we are going to fix with aluminum strapping guides. The electronics were laid out, wired temporarily until wire connectors are delivered and received on Monday and then permanently attached and connected. One of our team members made and attached an electronics plate on Tuesday and then made and attached the simple color wheel manipulation mechanism on top of the robot on Wednesday. The building team then continued to build a battery shelf. Our machine parts also came in on Wednesday and turned out perfectly! With some sanding and drilling they were put unto the bot. The electronics team was able to get basic code to run all the mechanisms and then shooter assembly began on Friday and completely finished on Saturday. Winding down to the end of the week, the shooter was mounted on the robot and tested. It is extremely powerful and it is expected to perform well once all the bugs are worked out. Bumper backings were measured, cut, and the front and back of the robot frame was resized so a guard rail is able to be ran on the sides, keeping the wheels from being completely exposed. The bot was then weighed and is 115 pounds out of the 125 pound weight limit. A lot of work had been done on the field element as well, and our partial field is almost complete. Decisions were finally made on shooting on the back of the robot instead of the front, and we will NOT be having a turret as we realize it will not be feasible, and limelight is still to be determined. Good Luck with us and everyone else as we continue into next week! The majority of the first half of the week was solving problems. There have been lots of issues figuring out how to drive the climbing mechanism. We are currently using chain to drive, but due to the shape of the mechanism, slack builds up once the climber is halfway extended until the chain is so loose that it just skips on the sprocket instead of doing any work. We also ran out of vital parts that had been ordered that should be here by the end of the week. On Thursday, we managed to build a solution to slack in our climbing mechanism. The building crew also mounted our full intake to the robot and are working on welding belts to use in the intake, though there were several significant issues that may or may not be problematic in the long run. Friday, progress was made on the second and third stages of the intake, attaching motors and welding belts. Progress is also definitely being made on the climber and is coming along, but we are still working on getting hooks and the crossbeam in place. By Saturday, a lot of catching up was done and the intake was completely finished being assembled. It was tested, though it did not work the first time, parts were 3D printed that should fix all of our problems. Our climber only needs hooks, which we should be able to retrieve off of Amazon, but in the mean time, our color-wheel manipulator has been cut and painted and should be ready to put on the bot by next week along with possibly laying out a plexiglass case on the "top shelf" of the robot to house all the electronics and the battery. A lot of small changes had been made

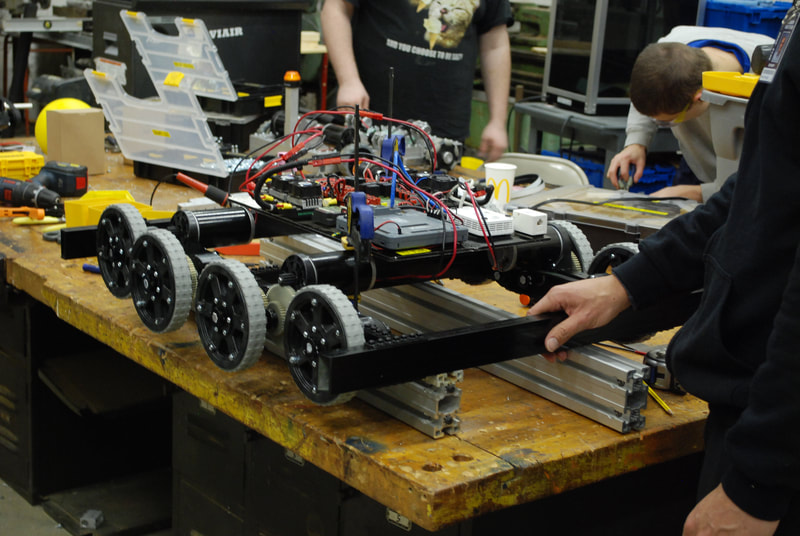

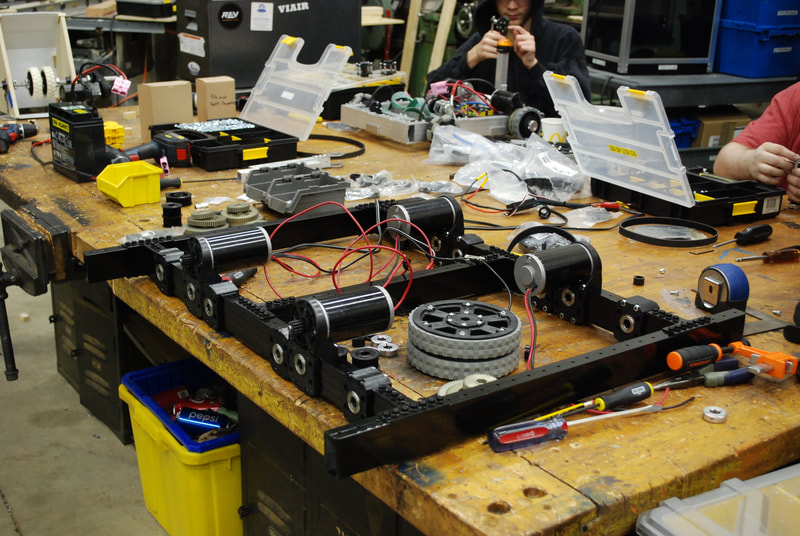

From starting to prototype the intake system to finishing the Peanut Bot, we have been able to accomplish so much and are starting to get farther ahead of where we usually are in development, but that does not stop us from continuing to push ourselves continuously when it comes to getting even more done whether on the building aspect, programming, or whatever needs to get done! Thursday, the team was able to add some finishing touches to our intake prototype, then cut pieces and began painting them, as seen below. We continued assembly of the intake, and also made some design decisions on the shooter and the hopper. Coming to a close of the week, we did a test with our shooter prototype after adding foam backing and a 5 pound flywheel, which shot a good 35 feet! In other news, Peanut Bot , Test Bot, and the 2019 competition bot have all been reprogrammed to use for demonstration purposes. Great things heading into next week! Starting off in the beginning of the week, we hooked up our shooting prototype to a bag motor to test if it would shoot the ball. We were able to launch it about 15 feet which is a good start, but that still leaves 15 to go. We were then able to test the shooting mechanism with a Neo motor, which worked wonderful! When it comes to our chassis, we were able to get it fully painted black (as pictured below) and assembled the four quarters of the drivetrain and run it at full speed! Getting into the middle of the week, Wednesday we spent most of the day finding and ordering certain parts that we had trouble finding for previous orders. Work was then done on our peanut bot trying to drive the front wheels with a chain rather than belts. This is a bot being built as a side project for when we have local events here in Buchanan! Thursday, more work was done on button and shirt designs, and we have our seasons bot almost completely assembled! Finishing off, we hooked up the Demo Board to the robot, then tested the drivetrain against a "boundary" and inch tall, and it drove over perfectly! There was much progress that was made, but there is still a long way to go!

Starting off with the beginning of the week, the team got together and configured design ideas and came up with this year's design of the robot. We took into consideration the different types of strategies we may possibly be able to use to help us aim for the win! With step one checked off the list, that leads us into being able to start ordering parts as we think about what we need to buy according to what our bot should accomplish for the 2020 Infinite Recharge season. On Wednesday, members of the team sat around and thought of gifts we could hand out to other teams! Closing in on the second half of the week, we continued to order parts, the build team built the drivetrain, started on the chassis, and started prototyping the lift. Great start to the beginning of the season! Recognition in all that we do. It’s not just building robots.

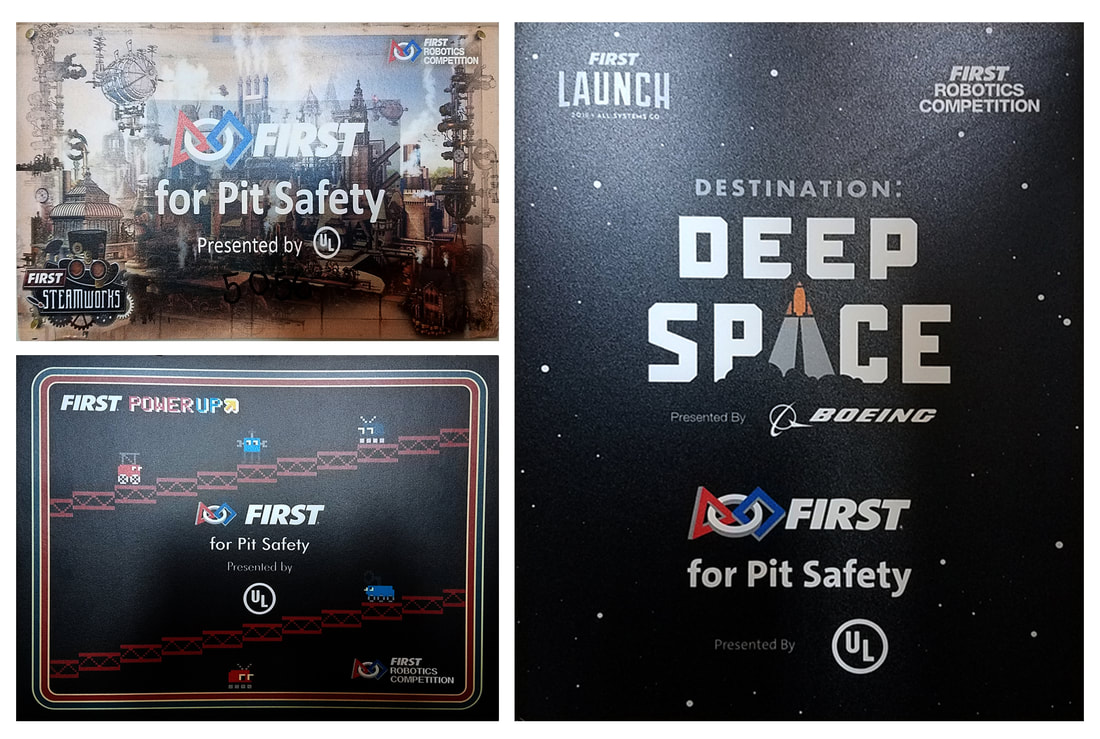

At each event, two teams are selected for the Pit Safety award which recognizes through the FIRST Safety Advisors an exemplary safety program. The safety team must go through an interview process and have the Safety advisors visit their pit. There are 40 teams at an event. Only two teams are chosen for this honor. I am very proud to announce that our safety teams beginning with Autumne in 2017, Erin in 2018 and now Erin and Serena in 2019 have received the Pit Safety award at not just our local event, but BOTH events for each of the last three years. Congratulations ladies, and thank you for keeping the team safe! |

MegaHurtz Team Blog

Archives

March 2024

Categories |

|

MegaHurtz Robotics | FIRST Team 5056

Buchanan High School, Buchanan Michigan |

Our financial partner is Lake Michigan STEAMWORKS

More information can be found at www.lakemichigansteamworks.org |

RSS Feed

RSS Feed